Use and Optimization of Pantograph Video CCTV System for EMUs

2024-02-18 09:20Abstract: The pantograph video monitoring system is essential for monitoring the status of high-voltage equipment of the rolling stock, which plays a vital role in improving the high-voltage system. It plays a crucial role in improving the efficiency of fault disposal and ensuring the operational safety of rolling stock. The system can effectively assist the train mechanic in carrying out emergency treatment of high-voltage equipment failure, which improves the disposal efficiency and compresses the stopping time. The degree of intelligence is not high for the system currently exists, relying on manual monitoring and inspection, by the outside environment interference, snow and ice weather use inconvenience and other problems. We propose using extensive data analysis, image intelligence analysis, and other technologies to optimize and improve system functions.

As a critical rolling stock component, it will lose its power supply when the pantograph fails. Not only does it cause the train set to lose power and stop in the interval, but also the passenger service facilities such as air conditioning, water supply, and sanitation will stop working. Seriously affect the comfort of the passenger. To improve the efficiency of high-voltage system fault disposal and ensure the safety of the rolling stock, this system plays an important role in ensuring the safe operation of moving trains and maintaining the order of high-speed rail transportation.

1. System application

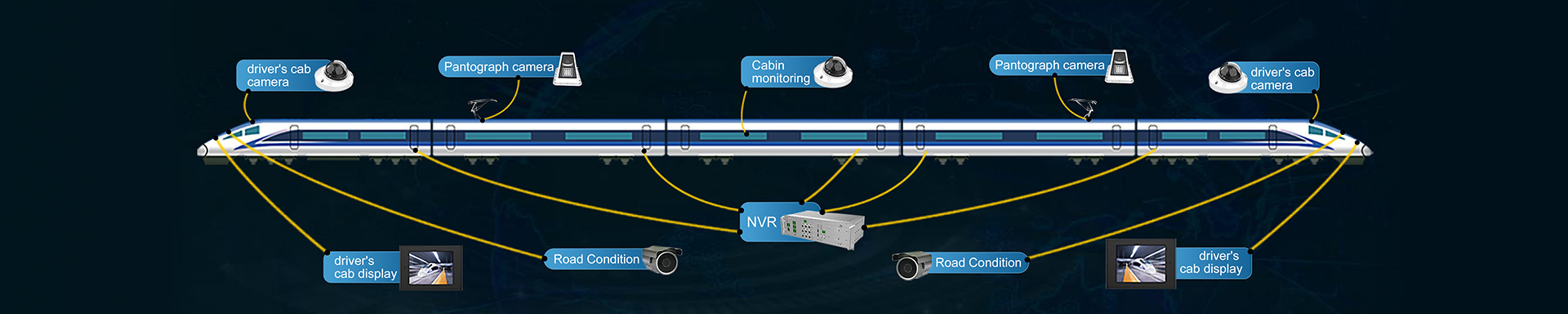

The video monitoring system of rolling stock consists of a pantograph camera, monitoring screen, pantograph video monitoring server, etc. It can intuitively monitor the working status of the pantograph and contact network on the roof of the car. It can take into account the operating status of the high-voltage equipment near the pantograph, which plays a vital role in monitoring the technical status of the rolling stock and the emergency disposal of high-voltage failure.

1.1 Monitor the appearance status of high-voltage equipment and pantograph flow conditions of rolling stock

During the operation of the rolling stock, especially in the windy season and ice and cold weather, the system can timely find the pantograph hanging foreign objects, abnormal appearance, poor flow and contact network wire icing, and other abnormal conditions (see Figure 1-4). Take necessary measures promptly to ensure the safety of the operation of the rolling stock.

1.2 Auxiliary for emergency disposal of high-voltage equipment failure

When automatic bow lowering, network side overcurrent, high voltage grounding fault occurs, check the working condition of high voltage equipment at the moment of weakness by playing back the system video.

To judge the fault's impact, provide the necessary reference and basis for the subsequent emergency treatment and analysis of the original fault flash.

1.3 Assist in the troubleshooting of contact network equipment

When the inspection in the warehouse reveals abnormalities such as damage to high-voltage equipment by striking, By playing back the pantograph monitoring video to determine the moment of failure, kilometer markers, and other information, Assist the power supply department in troubleshooting and processing.

By using the pantograph video monitoring system, the railroad vehicle department has improved the efficiency of high-voltage equipment fault disposal. The number of dismounting (boarding) inspections was significantly reduced, and the power supply department was assisted in discovering several faults, such as abnormal contact network positioners and loose suspension strings.

2. Problem Analysis

The use of the video monitoring system has improved the quality and efficiency of the emergency disposal of high-voltage equipment failure of the rolling stock and reduced the impact on the order of high-speed rail transportation. However, the system still has the problems of single inspection and monitoring means, low intelligence, and significant interference from the external environment, mainly in the following three aspects.

2.1 It cannot automatically identify and record abnormal conditions of high-voltage equipment.

Influenced by the complex and changeable environment Gonzo, the fault model is not yet perfect, etc.The system function is only limited to manual monitoring and inspection analysis, video recording, etc. It does not automatically identify abnormal conditions of high-voltage equipment and automatic extraction and recording of image information. It entirely relies on manual inspection and judgment, which is challenging to analyze, has a large amount of work, and affects the quality and efficiency of emergency fault disposal.

2.2 Without the remote transmission function

In the process of emergency disposal of high-voltage equipment failure, it is necessary to check and playback the monitoring video quickly and accurately. Since the current system uses single-vehicle storage and a centralized monitoring scheme, it does not have remote transmission capabilities. It only relies on the accompanying mechanic playback or uses the external network cell phone video after the return of the video, affecting the efficiency and quality of the simultaneous mechanic emergency troubleshooting.

2.3 Monitoring quality is affected by bad weather

The pantograph video monitoring quality in rainy and snowy weather is reduced due to rain and snow adhering to the surveillance camera glass. The system cannot be used generally in severe cases due to snow and ice accumulation coverage.

3. System Optimization

Through the use of extensive data analysis and Gonzaga intelligent analysis, the pantograph video monitoring system of the rolling stock can be upgraded and improved in the following aspects.

3.1 Realize intelligent analysis of high-voltage equipment faults

Due to the rapid background changes, complex lighting changes, and variable climatic environments during moving trains, the traditional image recognition accuracy is not high. Construction of pantograph structure and high-voltage fault feature recognition models using a combination of image morphology and deep learning modeling methods. Intelligent analysis technologies such as feature extraction, model matching, and image comparison are used to detect faults such as pantograph cremation, pantograph foreign object intrusion, pantograph abnormality, pantograph attitude, and camera blur.

3.2 Optimize system usage functions

According to the pantograph lifting bow state, the operating section contact network height (or pantograph head position characteristics), and other information, the monitoring camera automatically adjusts the function. To achieve the optimal monitoring effect. According to the high voltage fault alarm such as automatic bow lowering, net-side over-current of the moving train set or the intelligent system recognition of the situation to achieve automatic screenshot and storage of abnormal video clip function. Simplify manual operations and improve efficiency.

3.3 Realization of remote backhaul

Establish a pantograph video monitoring data transmission system. According to the network communication quality and ground technician analysis and diagnosis requirements, the communication network, load evaluation algorithm, and adaptive modulation technology. The frame number, speed, and bit rate of the pushed video stream are automatically adjusted according to the principle of quality first. Matching the video transmission process with the fluctuating network environment, thus realizing the remote return function of the pantograph monitoring video of the rolling stock. Ground technicians participate in pantograph fault diagnosis and analysis by playing the video together or broadcasting the fault record information on demand to improve the efficiency of emergency disposal of pantograph network faults.

3.4 Improved environmental adaptability

To strengthen the defogging and snow melting function of surveillance cameras, we increase the heating power of glass by optimizing the electric heating method of pantograph glass and using a special coating to reduce the rain and snow adhesion of surveillance camera glass. Improve the quality of video surveillance in bad weather such as rain, snow, and fog; optimize the image recognition algorithm and enhance the details of the critical parts of the monitoring through image enhancement technology. Highlight the aspects of concern (pantograph structure, etc.) and improve the accuracy of intelligent analysis in complex and variable light environments.

As an essential part of the onboard monitoring equipment of rolling stock, the pantograph video monitoring system plays a significant role in ensuring the operational safety of rolling stock and maintaining the order of high-speed rail transportation.Through intelligent image recognition, automatic control, communication, and snow removal technology, the system function can be further optimized and improved to improve the efficiency of emergency disposal of high-voltage equipment failure of the moving train set and to ensure the safety of the moving train set operation.