Why Does Every Train Need a Monitoring System Now?

2024-12-26 15:48

Have you ever wondered what keeps the railway network running smoothly? How do we ensure the safety of passengers and the reliability of trains? And, perhaps most importantly, how do we prevent accidents, optimize operations, and anticipate maintenance needs before they become costly problems? The answer lies in train monitoring systems—technologies that are no longer just an option but an essential part of modern railways.

Simply put, train monitoring systems are a game-changer. They don’t just enhance safety; they transform operational efficiency and reduce long-term costs. Whether you're looking to improve safety, streamline scheduling, or predict maintenance needs, the benefits of these systems are undeniable. Let's explore why every train needs a monitoring system and how it can benefit your operations today.

Let’s break down the specific advantages that these systems provide. From real-time safety monitoring to predictive maintenance and operational improvements, I’ll walk you through each critical aspect that makes train monitoring systems indispensable.

Why Train Monitoring Systems Are Essential for Safety?

Have you ever wondered how a train can stay on track, even under extreme weather conditions? Or how it can avoid accidents in busy or unpredictable environments? The key lies in real-time monitoring systems.

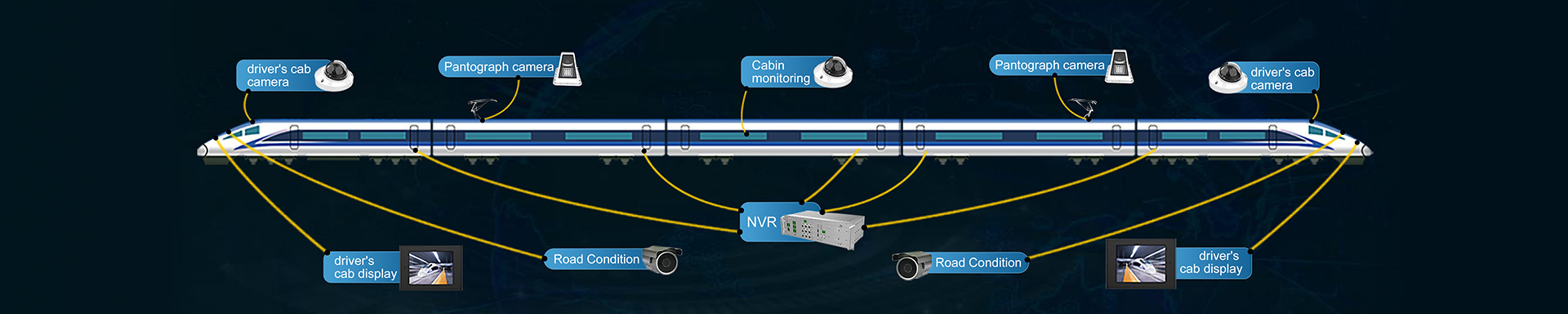

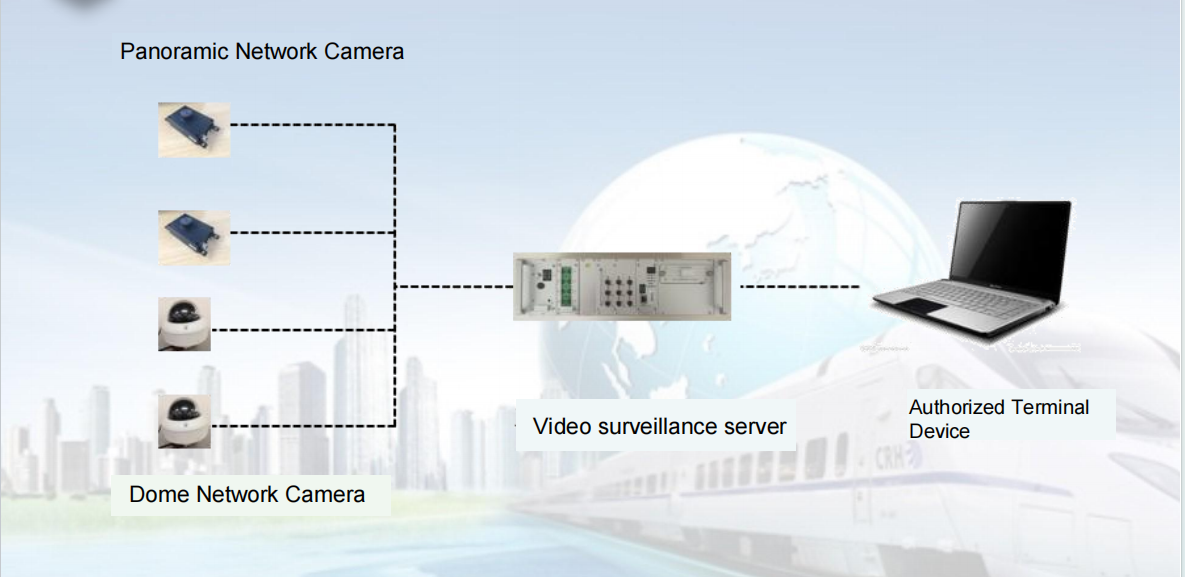

Train monitoring systems are vital in maintaining safety. Technologies like Automatic Train Supervision (ATS)monitor speed, track conditions, and automatically intervene when necessary to prevent accidents. Additionally, on-board video surveillance continuously checks critical components like brakes and wheels, alerting train operators about any abnormalities. This proactive monitoring can reduce human error and allow for quicker responses to potential threats, which ultimately saves lives.

These systems don’t just protect against immediate risks. They also ensure long-term safety by continuously collecting data from key components. Whether it’s monitoring the health of the train’s braking system or evaluating track conditions, the insights gathered help anticipate potential issues before they become severe, enhancing safety even further.

How Monitoring Systems Improve Operational Efficiency?

Have you thought about how to make your train schedules more efficient and ensure trains are always on time? It's not just about having enough trains running; it’s about optimizing their movements.

Train monitoring systems help with operational efficiency by enabling real-time data analysis and automated control. Technologies like Communication-Based Train Control (CBTC) allow operators to adjust schedules based on real-time conditions, such as weather, traffic, or even passenger demand. By continuously monitoring train speed, load, and environmental factors, these systems can minimize delays and improve reliability, ensuring that trains run on time and at full capacity.

Imagine a system that not only tracks train positions but also optimizes routes based on traffic conditions, passenger numbers, and even upcoming track maintenance. That’s the power of CBTC, which enhances operational efficiency by adjusting operations dynamically and in real-time.

The Role of Predictive Maintenance in Reducing Costs?

What happens when a critical component like the train’s engine or braking system fails unexpectedly? The financial and operational costs can be astronomical. How can you avoid these disruptions?

Predictive maintenance is one of the most powerful features of modern train monitoring systems. By continuously collecting data from sensors installed on various train components, the system can predict when a part is likely to fail. This allows operators to perform maintenance before the problem occurs, reducing both downtime and repair costs.

Rather than performing routine maintenance based on a fixed schedule, predictive maintenance is driven by actual data, allowing operators to target repairs only when necessary. For instance, when the brake system starts to show signs of wear, maintenance can be scheduled before the part fails, saving both time and money.

How Modern Rail Networks Benefit from Integrated Monitoring?

As railway systems expand and become more complex, how do we ensure smooth operations across an entire network? How do we manage the flow of trains efficiently and avoid bottlenecks?

The answer lies in integrated monitoring systems. By combining data from multiple sensors, on-board systems, and central control units, these systems ensure that everything from individual trains to the entire railway network is operating optimally. Integrated systems allow for better coordination, faster response times, and the ability to manage large-scale operations efficiently.

The future of rail transport is increasingly reliant on integrated monitoring systems that enable communication between different layers of the railway infrastructure—trains, tracks, and control rooms. This enables seamless management of the entire system, ensuring that trains run smoothly and safely across the network.

Conclusion

Train monitoring systems are no longer optional; they are essential for modern railway operations. These systems enhance safety, improve operational efficiency, and help reduce costs through predictive maintenance. With advancements in technology like CBTC and ATS, we can expect to see even greater improvements in the coming years.

If you’re managing a railway network or considering upgrading your fleet, implementing a monitoring system will help ensure that your operations are safe, efficient, and cost-effective.