Locomotive Pantograph CCTV System

2024-02-18 09:20I.Overview

With the continuous advancement of leap-forward development in the railway industry, the requirements for the locomotive system are increasingly high. The strict execution of standardized operation procedures by locomotive crew members is key to ensuring safe driving.

At present, video surveillance systems are essentially installed on all locomotives, enabling monitoring of key parts of the train. However, the pantograph of the locomotive, which serves as power transmission, has not been video monitored. The inability to observe the state of the pantograph in real time during actual operation, such as foreign objects invading the pantograph and abnormal pantograph components, makes it hard to analyze and determine responsibility. Maintaining the honor of the railway system, a video monitoring device for the pantograph is one of the most powerful pieces of evidence.

In response to this, the Shandong Tienuo Intelligent Co., Ltd. has developed a "Locomotive Pantograph Video Surveillance System" with the specification model RL-2052YH-SDG. This system utilizes high compression ratio digital processing technology and analog HD video encoding technology, conducting real-time image monitoring on the status of the locomotive pantograph, achieving full coverage of the pantograph's state.

The system has the following functional features:

The system supports real-time video display through a display terminal, and supports channel switching;

The system supports real-time video capture by the pantograph camera, with video recording directly recorded on the AV3 board hard disk;

The system's recording supports playback, cropping, and other operations using existing ground video analysis clients;

The pantograph camera in the system uses an analog HD camera, and the shell is made of glass fiber reinforced plastic material. The whole body is molded in a streamline design, which is suitable for installation on the top of the locomotive;

The system's connecting cables all use low-smoke halogen-free flame-retardant materials.

II.Environmental Conditions

2.1 Altitude Not exceeding 2,500 meters.

2.2 Environmental Temperature

2.2.1 Operating Temperature Pantograph Camera: -40°C to +70°C.

2.2.2 Storage Temperature -40°C to +70°C.

2.3 Relative Humidity

The maximum average relative humidity of the wettest month does not exceed 95% (the average minimum temperature of the month is 25°C).

2.4 Installation Conditions

The cameras installed outside the vehicle should be able to withstand wind, sand, rain, and snow.

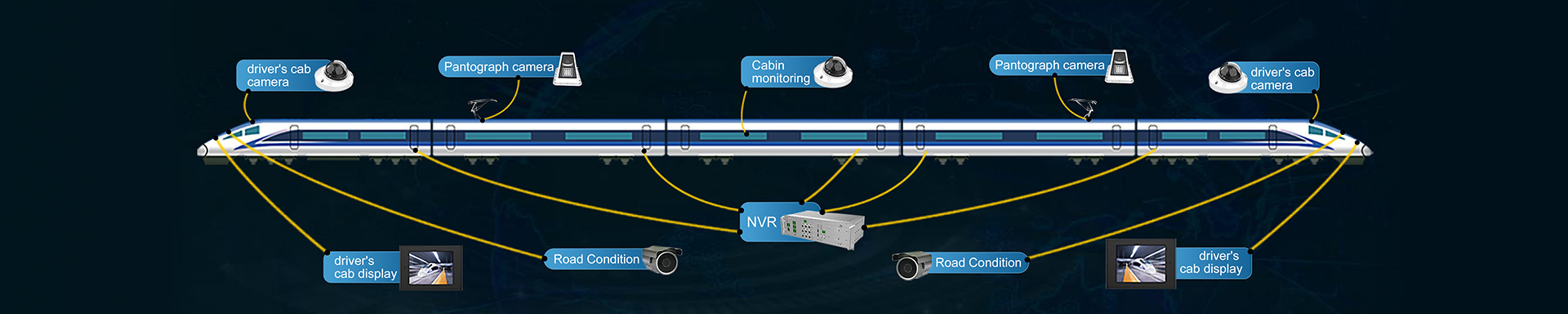

III.System Composition

A pantograph camera is added on top of the locomotive to make it easier for the driver to check and confirm the situation of the pantograph parts.

There are 2 cameras for each locomotive, one for each pantograph. Each camera is equipped with supporting fixed structural parts and protective covers. In addition, camera signal cables and power cables are added.

The pantograph video image monitoring of the locomotive stores the monitoring data synchronously and uses an audio-visual display terminal for video preview and fault alarm. Each video acquisition card supports 7 video acquisition channels, and the newly added pantograph camera for the HXD3 type locomotive is connected to channels 6 and 7.

IV.Pantograph Camera Technical Specifications

The frame rate for the pantograph monitoring video should not be lower than 8 frames/s, and the resolution should not be lower than 4CIF format storage;

Real-time collection of video data from the pantograph monitoring area, with video being the 7th channel for each acquisition card.

Type: Color camera;

Rated voltage: 12V;

Rated power: ≤5W (heating function off, supplementary light power 10W±15%), ≤25W (heating function on, supplementary light power 10W±15%);

Horizontal resolution (nominal): ≥700 TV Line, with the actual error not exceeding 10%;

Signal to noise ratio: ≥48 dB;

Lens focal length: 3.6mm;

Lens aperture number: F1.8;

Low luminance: Can work normally at 0.5LUX;

Housing requirements: Fiberglass;

Camera lens protective material: Tempered glass;

Protection level: IP67;

Structural requirements: Whole body molding process, streamline design, and cannot have sharp corners;

Functional requirements: Comes with supplementary light function, rain and snow and anti-dirt function, and glass heating function (temperature limit for activation can be set); Field of view coverage requirement: Should be able to cover the space area from 200mm above the contact network to inside the roof slider.

V.Overall Solution Explanation

Pantograph Camera Installation

The pantograph monitoring system is installed on the top of the locomotive and uses a special protective cover to integrate and protect the monitoring camera. The protective cover's center is approximately 3-5m from the center of the pantograph's bow position, and a through-hole is opened on the roof. The specific installation location will vary depending on the type of vehicle. The pantograph monitoring camera is streamlined in its entirety, with the outer cover made of fiberglass material, cast through an overall mold. It is connected to the body of the vehicle using six M12 bolts.

The pantograph camera comes with a white light supplementary lamp, which compensates for illumination in dark nighttime environments. To prevent the influence of rain and snow weather on the video monitoring quality, the camera comes with a heating glass function, which automatically starts when the temperature value for activation is reached, melting things like rain, snow, and frost.

As shown in the figure below:

Field of View Effect

The pantograph camera has a field of view angle of 70 degrees, a focal length of 4mm, and the field of view is most clear within the range of 3m-6m. The following image is a 1:1 simulation of the field of view coverage effect of the pantograph camera in the 3m-6m field of view using SolidWorks modeling.

Field of View Coverage Effect Diagram for Pantograph Camera