- Home

- >

Resources

In today's rapidly evolving world of transportation technology, staying updated with the latest advancements is crucial. One significant upgrade is the implementation of advanced CCTV technology on trains. This technology not only enhances security and safety but also revolutionizes the management and operational capabilities of railway systems.

The modern railway system necessitates robust security measures to ensure the safety and efficiency of its operations. Onboard CCTV solutions have emerged as indispensable tools in this regard, offering real-time surveillance, incident documentation, and deterrence against unlawful activities. Selecting the right CCTV solution involves evaluating several critical factors, including image quality, system durability, technological innovation, and customer support. This article explores the top five companies renowned for their onboard CCTV solutions tailored for locomotives.

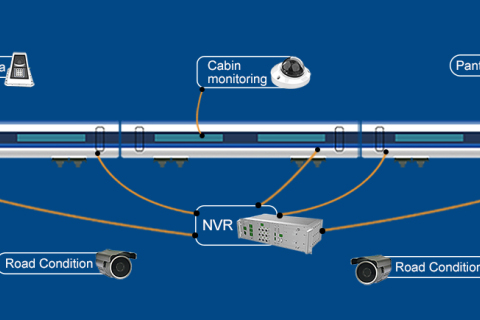

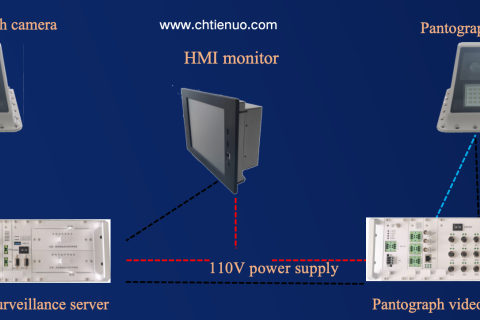

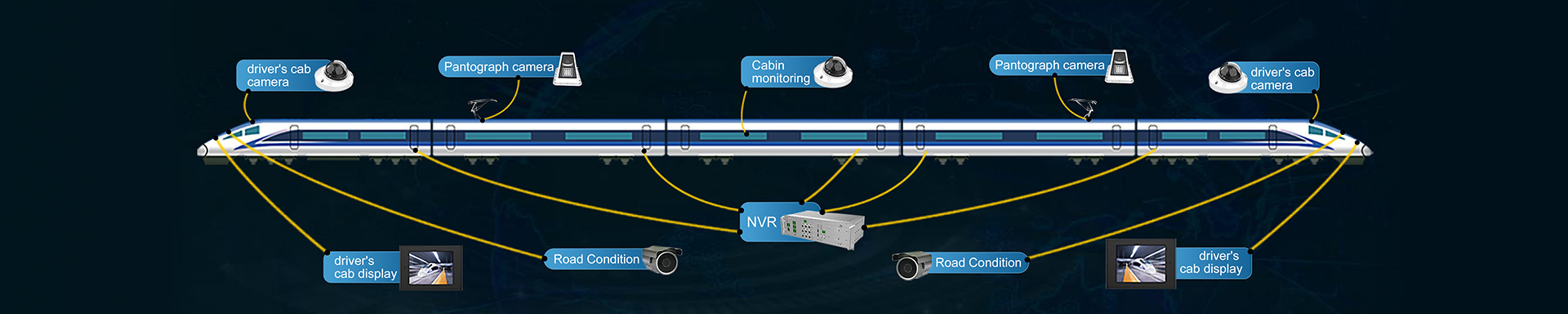

As a high-tech enterprise integrating R&D, manufacturing, and sales, we have become a leading provider of rail security and information technology products and solutions. Today, we proudly present our groundbreaking product – the direct-power mobile video surveillance device for passenger trains.

In the evolving landscape of public transportation safety and efficiency, Closed-Circuit Television (CCTV) in-train surveillance systems are playing a pivotal role. These systems are designed to enhance security, improve operational efficiency, and ensure passenger safety on rolling stock, including trains and trams.

In an era where passenger safety and operational efficiency are paramount, on-train Closed-Circuit Television (CCTV) systems have emerged as a critical component of modern railway operations. These advanced surveillance systems offer far more than mere passenger safety; they are a cornerstone in the technological advancement of railway systems worldwide.

A pantograph camera is used for monitoring the condition and performance of pantographs on electric trains, trams, or electric buses. Pantographs are the apparatus mounted on the roof of these vehicles that collect power from overhead lines. The camera systems are designed to: Monitor Pantographs in Real-Time: They provide continuous surveillance of the pantograph's condition, checking for proper positioning, sparking, and other potential issues that could lead to damage or malfunction

As the world becomes more interconnected, the need for reliable and efficient transportation systems is more crucial than ever. One key player in this domain is the onboard CCTV system for rolling stock, a vital component for ensuring safety and security in the railway industry. In this post, we'll explore the top 5 companies in India that are making significant strides in this field.

TIENUO's Locomotive Pantograph CCTV System is a security game-changer, offering real-time surveillance of critical train operations. By minimizing unforeseen failures, it enhances service reliability and safety. Tailored to fit unique needs, our products not only meet but surpass industry standards. Choose TIENUO for quality, efficiency, and the confidence of safety.

In the fast-paced world of transportation, safety and security are paramount. Onboard CCTV systems for rolling stock are essential for monitoring and ensuring the well-being of passengers and crew. Here's a look at the top 5 companies in the UAE that are leading the way in this specialized field.

The global market for rolling stock Passenger Information Systems (PIS) is booming. Every day, billions of people rely on these systems to navigate their travels. From simple seat availability data to complex station-specific broadcasts, these systems form the backbone of modern transportation logistics. This article aims to enlighten the reader about the top ten global companies that lead the PIS market for rolling stock.

Before the merger of CNR and CSR, the major locomotive and rolling stock manufacturers in China were the manufacturing companies under these two groups. The two major manufacturers of locomotives are CRRC SIFANG and CRRC CHANGCHUN Railway Vehicles Co.,ltd. In 2004, in the China Harmony technology introduction negotiation, because foreign technology manufacturers could not be bidders, they had to participate in the bidding by joint venture or technology transfer with domestic manufacturers. In this process, Bombardier was the first to set up Qingdao Sifang Bombardier Railway Transportation Equipment Co. After that, Sifang Locomotive and Kawasaki Heavy Industries joined hands to focus on the CRH2 series. Changchun Railway Vehicle, which initially wanted to cooperate with Siemens, turned to Alstom because the negotiations did not go well; Siemens made a compromise in 2005 and joined hands with Tangshan Railway Bus to produce CRH3C. In 2004 and 2005, China's rolling stock manufacturers formed a four-company pattern through two technology introductions. The former China North Railway Group's CRRC changhun railway and CRRC tangshan and China South Railway Group's Sifang Locomotive and BST. Later, China South Railway and North Railway merged to form the China Railway Group, but these four companies manufacture most of China's rolling stock. In the era of "Fuxing"locomotives, Puzhen vehicles joined the production team again.

The pantograph monitoring system is an integral part of modern railway surveillance, designed to ensure the continuous and efficient operation of trains by providing real-time monitoring of the pantograph's performance and status. The pantograph, a critical component of electric trains, is responsible for maintaining contact with the overhead lines to draw power for the train's propulsion and systems.